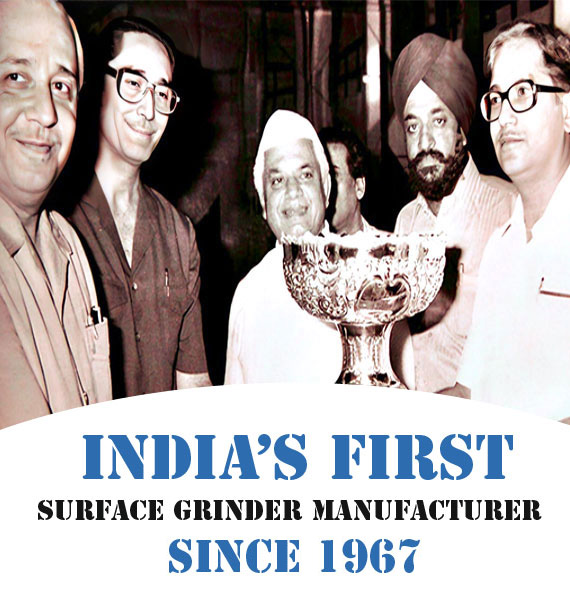

Hydraulic Surface Grinder Manufacturer - Original Bhurji (ISO Certified Since 1967)

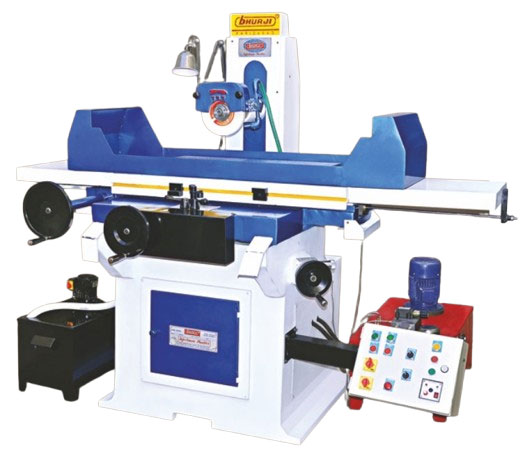

Bhurji’s Hydraulic Surface Grinder

Bhurji is a trusted Hydraulic Surface Grinder Manufacturer in India, offering high-precision and durable grinding machines for various industries. Our hydraulic surface grinders are designed for smooth, vibration-free operation, ensuring accurate and efficient grinding of metals and other materials.

Under the leadership of Mr. Vikram Singh Bhurji, we focus on innovation and advanced engineering to deliver machines that enhance productivity. Our grinders feature a robust hydraulic system, user-friendly controls, and superior surface finishing capabilities, making them ideal for workshops and manufacturing units.

With a strong commitment to quality, Bhurji ensures that every hydraulic surface grinder meets international standards and provides long-lasting performance. Whether you need a reliable grinding solution for small-scale or large-scale operations, we have the perfect machine for you. Contact us today for the best hydraulic surface grinders in India at competitive prices!

Why Choose Bhurji as Your Hydraulic Surface Grinder Manufacturer?

-

+

ISO Certified Quality:

Ensuring high-precision grinding solutions for industrial applications.

-

+

Since 1967:

Over 50 years of trusted experience in manufacturing surface grinders.

-

+

Beware of Counterfeits:

Only Original Bhurji Surface Grinders guarantee premium quality and durability.

-

+

Heavy-Duty Build:

Long lifespan, minimal maintenance, and rugged construction for industrial use.

-

+

Precision Grinding:

Ideal for tool rooms, workshops, and precision engineering.

-

+

24/7 After-Sales Support:

Genuine spare parts, expert assistance, and hassle-free service.

Bhurji's Range of Hydraulic Surface Grinder

AA Series

The AA Series hydraulic surface grinders are designed for high-precision grinding with smooth hydraulic movement. These machines ensure superior surface finishing, making them ideal for tool rooms and production units. Built for durability, they provide reliable performance.

AK Series

Our AK Series hydraulic surface grinders feature advanced hydraulics for effortless operation and consistent accuracy. With a rigid structure and user-friendly controls, they are perfect for industries requiring high-efficiency grinding solutions for metals and other materials.

SCM Akom Series

The SCM Akom Series is engineered for ultra-precision grinding applications. These hydraulic surface grinders offer excellent stability, vibration-free operation, and superior finishing quality, making them the preferred choice for industries demanding the highest accuracy and efficiency.

Trusted by Industries, Built for Precision!

Experience durability and accuracy with our hydraulic surface grinders. Talk to our experts for tailored solutions today!

Features of Hydraulic Surface Grinder

Bhurji’s Hydraulic Surface Grinders are designed for precision, durability, and high efficiency. Key features include:

-

+

Optimized Design Structure:

Microfeed Hydraulic Surface Grinders are robust and simple in design but accurate and efficient as well as most suitable for the tool room and production jobs. The Cross Slide a on Double-V which is best for Hydraulic Machines for rigidity and stability.

-

+

Hydraulic System:

Surface Grinders are fitted with Compact Hydraulic Power Pack (dust proof) with an exclusively designed control unit incorporated within the body of machine. The said system does not require any sexdins load. The required pressure of drains through a fine filter, before entering the Tank. The Hydraulic Tank is fitted outside to eliminate any heat and vibrations.

-

+

Wheel Head:

Ultra precision hardened Nitrallcy Spindle Egrease pecked for long life) runs in antifriction bearings and directly driven by flange mounted motor (to eliminate any vibration) rough flexible couplings. Its production and testing passes through rigorous inspection at manufacturing stages to ensure smooth and trouble free running and sensitivity essential for extra ordinary finish. The Spindle housing is supported in Vertical Column which is heavy duty, ribbed and stationary.

-

+

Longitudinal Traverse & Cross Movement:

The Magnetic Table travels on Vee & Flat Guide-way and is driven through a hydraulic cylinder, having provision of continuous lubrication. The Cross Movement ion Double V Gudeways through Electric Motor for fine and incremental grinding.

Specification of Hydraulic Surface Grinder

| A-818 | A-1024 | AA-1224 | AA-1230 | AA-1000 | |

| Max. Table Grinding | 200 X 450 | 200 X 600 | 300 x 60 | 300 x 750 | 300 x 900 |

| Max. Magnetic Table Travel | 250 x 500 | 250 x 650 | 350 x 650 | 350 x 800 | 400 x 1000 |

| Max. Grinding Height under Wheel | 225 | 250 | 260 | 275 | 285 |

| Grinding Wheel Head Motor Speed | 2800 rpm | 2800 rpm | 2800 rpm | 2800/1400 rpm | 1400 rpm |

| Grinding Wheel Size (D x x x x ) | 180 x 31.75 x 13 | 200 x 31.75 x 13 | 200 x 31.75 x 13 | 200 x 71 x 20 (opt.) | 250 x 71 x 20 (opt.) |

| Hyraulic Tank Capacity (Telus 68) | 35 Ltrs. | 60 Ltrs. | 60 Ltrs. | 70 Ltrs. | 80 Ltrs. |

| Hydraulic Pump Motor | 1 HP | 1 HP | 1.5 HP | 1.5 HP | 2 HP |

| Auto Gross Feed Increment (Motorised Model Only) |

0.2 - 5.0 | 0.2-5.0 | 0.2 5.0 | 0.2 5.0 | 0.2 5.0 |

| Max. Longitudinal Table Speed | 15 M/min | 15 M/min | 15 M/min | 15 M/min | 15 M/min |

| Vertical Feed Graduation | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Cross Feed Graduation | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Working Pressure | 12 Kg/cm2 | 12 Kg/cm2 | 12 Kg/cm2 | 12 Kg/cm2 | 12 Kg/cm2 |

| Net Weight | 1100 Kg | 1200 Kg | 1350 Kg | 1500 Kg | 1650 Kg |

| Wooden Case Dimension (L x x x H ) | 1050 x 1500 x 1700 | 1050 x 1800 x 1700 | 1200 x 2100 x 1800 | 1200 x 1500 x 1700 | 1350 x 2300 x 1900 |

Why Bhurji Surface Grinders (Akom Series) Are the Industry Standard

(Avoid Costly Mistakes with Cheap, Low-Quality Alternatives!)

| ☑️ Features | ✅ Bhurji Surface Grinders (Akom Series) | ⚠️ Counterfeit & Local Competitors (Actual Losses) |

| ✔️ Authenticity | Original Akom Branded, Registered Trade Mark | Fake Branding, No Legal Protection |

| ⚙️ Build Quality | ISO-Certified, Heavy-Duty Materials | Cheap Materials, Prone to Breakdowns |

| 📏 Accuracy & Precision | Consistent High Precision for Industries | Inaccurate Grinding → *Defective Final Products* |

| 🔩 Durability | Long Lifespan, Minimal Maintenance | Frequent Repairs → *High Downtime & Extra Costs* |

| ⚠️ Business Reputation | Trusted by Leading Industries | Poor Machine Performance → *Loss of Customers & Trust* |

| 🔧 After-Sales Support | 24/7 Service & Genuine Spare Parts | No Support → *Wasted Investment in Repairs* |

| 📉 Financial Loss | High ROI, Competitive Pricing | Cheap Initial Cost → *More Expenses in Repairs & Downtime* |

Facing These Surface Grinding Problems? Bhurji Has the Solution!

(Stop Wasting Time & Money on Low-Quality Machines!)

| ❌ Common Problem | ✅ Bhurji’s Solution |

| Low Machine Accuracy – Leads to uneven surfaces & rejected workpieces. | Micron-level precision with high-accuracy engineering. |

| Frequent Breakdowns – Poor durability increases downtime & costs. | ISO-certified components ensure long-lasting performance. |

| High Maintenance Costs – Frequent servicing raises operational expenses. | Designed for smooth, low-maintenance operation. |

| Counterfeit Products – Duplicate grinders reduce productivity. | *Look for Akom Branding* to ensure authenticity & reliability. |

Our Esteemed Clientele

At Bhurji, we take immense pride in serving a diverse range of clients across various industries. Our products, including precision surface grinders, have earned the trust of leading companies worldwide.

Copyright © 2025 Bhurji Ltd. All Rights Reserved | Area We Serve